Over the years, MAS has given prominence to identifying, analysing, and mitigating the environmental impact of our operations; driven by a core principle to leave our planet better than we found it.

Today, this pillar of the Plan for Change reaches beyond our manufacturing locations; to advance environmental sustainability within the industry, and effect positive change throughout our sphere of influence.

Limit Emissions

Our actions to limit emissions, embrace the energy transition, and inspire climate action, are allied with the concerted global effort to tackle climate change. The commitments we have made, for our business and our supply chain partners, reflect this responsibility to align business strategies and ambitions with the journey toward a low-carbon future.

In 2024, we achieved 24.04% absolute reduction in our emissions footprint (measured against a 2019 baseline), surpassing our annual target of 21%. This continues the incremental gains made over the past years, and marks strong and steady progress toward our SBTi validated 2025-target of 25.2%.

We have adjusted and restated prior years’ emission information, to reflect new acquisitions, and changes in control, and removal of facilities from the Group’s operational boundary. As per these changes, and in order to more accurately represent the Group’s actual emission footprint, MAS is in the process of proposing revised SBTi targets for 2030 in line with an adjusted baseline and new SBTi guidance.

Our progress in 2024 is the effect of a combination of strategic initiatives: including continued scale-up of solar power generation and transformation of renewable-energy management; strategic Power Purchase Agreements (PPA) with reputed utility providers; validation of green energy through Renewable Energy Certificates (RECs); prioritisation of sustainable energy sources such as biomass; and continuous energy efficiency improvements across our operations; coupled with strategic business adjustments. Renewables now make up approximately 39% of our energy-mix.

We utilise emission-intensity and energy-intensity as metrics to analyse and monitor the efficiency of our operations and effectiveness of our emission-reduction initiatives. In 2024, the energy intensities of both Apparel Manufacturing and Textile Production saw a significant decline, even though emission-intensities saw a marginal increase.

As we continued initiatives to address Scope 3 emissions and decarbonise the supply chain; we achieved 45% spend coverage for obtaining SBTi commitments: signifying almost half of our suppliers by-spend who have set their own science-based targets. While this is a reduction from 2023, reflecting the challenging business environment, we will continue to advocate for decisive action amongst our partners as we work toward the SBTi validated target of 85% suppliers by spend and 100% joint-venture partners. We also focused on refining and improving the calculation of our Scope 3 emissions. This involved improvements to the methodology, inclusion of new data-points, and increasing of accuracy for impact calculations. In 2024 we also set in motion a series of strategic structural and cultural shifts to address and reduce Scope 3 emissions in the years ahead.

Moving forward into 2025, we are committed to intensifying our efforts across these crucial areas. We will capitalise on opportunities for emission footprint reduction, continue to expand our renewable energy capacity, strengthen our sustainable biomass supply chain, and drive enhanced engagement and impact throughout our value chain.

Scope 1 and 2 – Direct and indirect emissions of our operations

GRI 305-1, 305-2

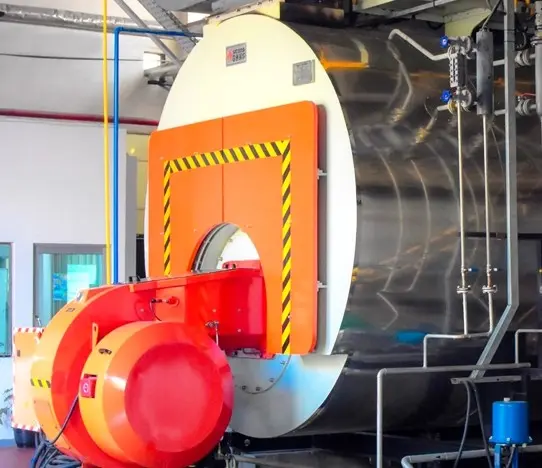

In 2024, we continued to implement measures to reduce our direct (Scope 1) emissions – prioritising efficient production process, especially for dyeing operations; reducing onsite electricity generation from diesel generators; and enhancing the benefits of sustainable biomass, including for steam generation to decrease the use of Heavy Fuel Oil (HFO). Scope 1 emissions for the year amounted to 64,449.48 TCO2e, while Scope 2 emissions reached 76,006 TCO2e.

Scope 2 emission reduction efficiencies included expanding our solar net metering system to cover 18 Sri Lankan facilities; selecting energy-efficient machinery when pursuing new acquisitions; purchasing IRECs covering Sri Lanka, Jordan, and Vietnam; completing agreements on RECs for all our Indonesia facilities – aiming for 100% renewable grid energy; and finalising financial Power Purchase Agreements for our IFI Facility in India.

| 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | |

| Target emissions (TCO2e) | 184,894.87 | 177,129.29 | 169,363.70 | 161,598.12 | 153,832.53 | 146,066.95 |

| Actual emissions (TCO2e) | 184,894.87 | 149,427.93 | 171,132.02 | 169,150.49 | 147,227.19 | 140,455.14 |

| Expected reduction (%) | – | 4.2 | 8.4 | 12.6 | 16.8 | 21 |

| Actual reduction (%) | – | 19.2 | 7.4 | 8.52 | 20.37 | 24.04 |

GHG EMISSIONS AGAINST BASELINE

EMISSION REDUCTION AGAINST TARGETS

SCOPE 1 AND 2 EMISSIONS BY SOURCE

GRI 302-3, 305-4

Absolute emission reduction, coupled with successful implementation of process and production efficiency programmes, saw reductions in energy and emission intensity of our Apparel Manufacturing operations. Energy intensity stood at 17.79 MJ/SH (19.18 MJ/SH in 2023), while emission intensity was recorded at 0.91 kgCO2e/SDH (1.00 kgCO2e/SDH in 2023). Similarly, Textile Production operations saw a significant improvement in energy intensity to 106.69 MJ/kg, from 161.22 MJ/kg in 2023, even though emission-intensity increased to 12.63 kgCO2e/WP in 2024 (10.586 kgCO2e/kg in 2023).

Scope 3 – Emissions across our value chain

GRI305-3

Our gross Scope 3 emissions in 2024 amounted to 1,225,958.85 TCO2e, reflecting a minor decrease from the previous year, despite addition of new data points for upstream emissions related to purchased fuels. Purchased goods and services contribute the majority of our emissions along the value chain (67%); while upstream and downstream transportation and distribution contribute an additional 18%. Employee commuting (4%) and end-of-life treatment of sold products (5%) are the other significant, addressable, categories of Scope 3 emissions.

In 2024, upon research and consultation with experts, we have adjusted the boundary of our Scope 3 emissions to not consider category 11, use of sold products, in accordance with allowances in the GHG Protocol guidelines. Additionally, newly acquired facilities were included in calculations.

Group GHG Emissions 2024

GRI305-5

In 2024, we focused on refining and improving the measurement and estimation of our Scope 3 emissions, including the trial of new databases for more accurate product impact calculations. This involved improvements to the methodology and use of data points for foreign travel and capital goods, new data points for fuel transport emissions, attention to upstream emissions related to fuel and purchased electricity, and expansion of considerations for purchased goods and services (category 1) to include services-related data.

Addressing emissions in the apparel value chain

The apparel value chain involves an intricate web of suppliers, service-providers, and business partners involved in bringing products to market. Emissions across the value chain, as measured by Scope 3 emissions, continue to represent the largest share of emissions related to producing apparels.

While measuring and addressing these emissions present a significant challenge, we believe that it also represents a tremendous untapped potential for emission-reduction through impactful change.

Alongside our efforts to improve data collection and reporting, we are also working closely with our partners to address and reduce future emissions across the value chain. Commitments to emission-reduction by our suppliers, coupled with our forward-looking product strategy; are expected to deliver considerable emission-reduction results in the years to come.

- Onboarding supply chain partners to commit to SBTi.

- Increasing recycled RM content in product composition.

- Investing in recycling technologies that enable fibre-to-fibre recycling.

Other significant emissions

GRI305-6, 305-7

The Group’s environmental management processes include regulations and monitoring of air quality and other air emissions from our facilities, in compliance with local regulations and international best practices. While our operations do not use Ozone Depleting Substances (ODS) for primary processes, products, or services, we account for the presence of hydrochlorofluorocarbon (HCFC) in Heating, Ventilation, and Air-Conditioning (HVAC) systems. Our efforts to phase-out ODS are aligned to regulator-driven stipulations in the areas we operate, including Sri Lanka – where HCFCs are planned to be phased out of the market by 2030.

| 2024 | Share (%) | |

| Ozone Depleting Substances (ODS) (TCO2e) | 1,199.22 | 100 |

| CO (kg) | – | 63 |

| NOx (kg) | – | 25 |

| SOx (kg) | – | 7 |

| Volatile Organic Compounds (VOCs) (kg) | – | 1 |

| Particulate Matter (PM) (kg) | – | 5 |

Energy transition

GRI302-1 , 302-2, 302-3, 302-4, 302-5

In 2024, our total energy consumption from non-renewable sources amounted to 972,507.41 GJ, with energy consumption from renewable sources standing at 614,554.31 GJ; resulting in total recorded energy consumption of 1,587,061.72 GJ. Overall energy consumption reduced marginally year-on-year, while energy from renewable sources grew by almost 10%; as we increase energy-utilisation from solar, biomass, and Renewable Energy Certificates (RECs). Renewables now make up approximately 39% of our energy-mix, up from 35% the previous year.

SHARE OF RENEWABLES IN THE ENERGY-MIX

RENEWABLE ENERGY BY SOURCE

We achieved an overall reduction in energy consumption in 2024, partly aligned with the scale of business for the year, but also owing to conservation and efficiency projects carried out at a number of our major plants.

Energy Management at MAS KREEDA

GRI 302-4

Division-level energy management and engineering advances implemented during 2024 have enabled MAS KREEDA to achieve significant reductions in energy consumption. These ongoing initiatives will help the Group realise gross energy savings of over 300,000 kWh (1,000 GJ) per year.

- Continuous compressed-air leak-rectification programme (65,400 kWh/year).

- Conducting a series of tests to identify and rectify compressed-air leaks on the production floor. Followed by assessments to quantify effectiveness of energy-saving measures.

- Compressor room heat elimination (5,600 kWh/year saving).

- Improved insulation and exhaust-control for compressors and dryers to reduce the overall compressor intake temperature.

- High and low-pressure separation in compressed air systems (53,400 kWh/year saving).

- Innovative plant-level optimisations that divided the compressed-air system to meet separate low-pressure and high-pressure needs, thereby reducing overall load on compressors.

- Compressor room rearrangement at Shadeline (143,000 kWh/year saving).

- Overhaul and rearrangement of piping pathways and improvement of temperature controls in the compressor room; leading to reduced transmission and distribution pressure-loss and optimisation of compressor-use.

- Installation of digital timers for lighting systems (39,600 kWh/ year saving). New digital timers at our canteens allowed for improved automation of lighting control.

Sustainably sourced biomass remains a crucial component of our

energy transition strategy, as outlined in our Approach to

Managing

Energy and Emissions. In 2024, we continued to purchase biomass from reputed

vendors, as per the MAS Sustainable Biomass Standard, with 5%

of total biomass purchases sustainably sourced. In addition,

we improved our systems to disaggregate and record biogenic

emissions, from utilisation of biomass, at our facilities.

Project Prithivi: Sustainable Biomass Supply for the Future

-

Transitioning to cleaner energy sources, such as

sustainably sourced biomass, is a colossal undertaking.

MAS operations in Sri Lanka, at the MAS Fabric Park

(MFP) and Biyagama Export Processing Zone (BEPZ), require approximately 320 tons of biomass per day (112,500 tons per annum).

Project Prithivi, our sustainable sourced biomass cultivation initiative at MFP, is an ambitious initiative to secure a sustainable energy-future for MAS. The project focuses on establishing and gradually scaling up a traceable supply of biomass; ensuring we meet our energy demands from cleaner sources, while responsibly managing potential environmental impacts.

Key Elements of Project Prithivi

- Target Species: Gliricidia sepium, a fast-growing, medium-sized tree that reaches heights of 10-12 meters (33-39 ft). This species is ideal due to its rapid regeneration capabilities.

- Cultivation and Harvesting Cycle: Once planted, the first pruning can occur just one and a half months later. The initial harvest is planned after a three-year maturity period, with subsequent harvests projected twice a year, ensuring a consistent supply of biomass.

- Scale and Yield: The current project spans over 70 acres, with a planting density of approximately 4,800 plants per acre (based on a 3ft x 3ft spacing). Each mature tree is expected to yield around 7 kg of biomass per harvest.

- Energy Efficiency: Gliricidia wood boasts a strong calorific value, typically ranging from 15 to 20 MJ/kg. This makes it an efficient and effective renewable energy source for our biomass-powered operations.

Project Prithivi is a long-term initiative with a medium time-horizon for returns. The first harvest, from 70 acres, is expected within three years. We expect to gradually expand the programme, which would improve the overall sustainability of our biomass supply. We have plans to enroll this new source of internal biomass supply, from Project Prithivi, with the SLS 1551:2016 standard; coinciding with ongoing sustainable-sourcing processes that apply to our main external suppliers of biomass. This will enable stronger traceability from field to gate, preventing natural forest encroachment or illegal harvesting and verifying biomass supply transparently.

With regard to solar PV generation, all MAS facilities in Sri Lanka transitioned from Net Accounting and Net Plus schemes to the Net Metering scheme in 2024. Under the Net Metering scheme, excess solar energy generated by our facilities is fed back into the national grid, resulting in reduced electricity costs. This change has also enhanced energy security at our locations and contributed to significant reductions in emissions due to the increased use of clean, renewable solar energy.

Transform Waste

GRI 306-1, 306-2

We are committed to innovating sustainable solutions that reduce the fashion industry’s waste footprint – within our operations, and across the apparel value chain. We are guided by the principle of waste as a valuable resource that can be transformed to create new value, while also minimising environmental impact.

Our efforts for value enhancement of waste are fuelled by continuous innovation, sustained through ongoing waste minimisation measures, and enhanced through collaborative engagements and partnerships.

In 2024, we made outstanding progress against our waste-related targets by driving new value enhancement initiatives, transforming waste streams across our operations and value chain, and redoubling our efforts to monitoring, train, and raise awareness amongst our people.

While the overarching goal of 100% value enhancement remains extremely ambitious, we have made significant progress in recent years through careful study of the potential of waste in terms of function, material, and structure; close monitoring of waste streams and waste management processes; and pioneering of innovative waste valorisation methods including recycling, reuse, and waste to energy operations.

However, in order to align our sustainability commitments with current realities while still holding ourselves to ambitious, forward-driving standards We have re-established our overall total non-hazardous waste value enhancement target to 80%, which is already a stretched target. This recalibrated goal is consistent with our expected performance and ensures transparency, accountability, and credibility in our reporting.

By the end of the year, we exceeding our internal target by a significant margin – achieving 76.2% of all non-hazardous waste value enhanced, up from 70.5% the previous year.

Rationale for adjusting our Transform Waste target

MAS’s fabric waste portfolio comprises a complex and diverse mix of materials ranging from cotton, polyester, and nylon to blends incorporating elastane and other specialty fibers. When we set our original target in 2019 aiming for 100% value enhancement of fabric waste it was based on the belief that textile-to-textile (T2T) recycling would soon be commercially viable at scale. At the time, we were actively collaborating with several innovative partners whose technologies showed promise in supporting this ambition.

Over the past five years, we have pursued this goal with determination. However, our journey has been shaped by significant external disruptions, including the COVID-19 pandemic, global economic headwinds, and delays in the development and commercialisation of key recycling technologies. Several of the early-stage solutions we engaged with faced critical hurdles ranging from difficulties in validating processes, or scaling challenges, to shifts in business focus or discontinuation of operations altogether.

While a few T2T recycling solutions have recently shown potential, their large-scale implementation remains unlikely before 2026. These realities have directly impacted our ability to achieve the original target within the planned timeframe.

Despite these setbacks, MAS has made substantial progress. As of end-2024, we have achieved 76.15% total non-hazardous waste value enhancement.

To align our sustainability commitments with the current realities while still holding ourselves to ambitious, forward-driving standards We are re-establishing our overall total non-hazardous waste value enhancement target to 80%, which is already a stretched target. This recalibrated goal is consistent with our expected performance and ensures transparency, accountability, and credibility in our reporting.

At MAS, we remain deeply committed to advancing circularity in textiles, and we will continue to focus on this effort by

- Investing in emerging solutions,

- Partnering with innovators in the recycling space, and

- Seeking scalable, commercially viable pathways to maximise the value of our fabric waste.

Transparency is a core value for MAS, and we will continue to report candidly on our progress, challenges, and evolving approach as we work toward long-term impact.

Our waste footprint

GRI 306-3, 306-4, 306-5

In 2024, total waste generated across our operations amounted to 23,929 MT, with a significant 13,954.51 MT diverted from disposal through preparation for reuse and recycling – both onsite and offsite. Of the waste directed to disposal; the majority was disposed through energy recovery and sanitary landfilling, with some non-hazardous STP sludge and ash also being used for land application as fertiliser.

| 2023 | 2024 | |||||

|

Total waste generated |

Waste diverted from disposal |

Waste directed to disposal |

Total waste generated |

Waste diverted from disposal |

Waste directed to disposal |

|

| Hazardous waste (MT) | 898.89 | 62.37 | 836.52 | 1,000.54 | 83.62 | 916.92 |

| Other non-hazardous waste (MT) | 6,557.44 | 6,326.74 | 230.69 | 5,944.70 | 5,643.12 | 301.59 |

| Non-hazardous RM waste (MT) | 16,652.94 | 7,791.21 | 8,964.82 | 16,983.96 | 8,227.77 | 8,756.19 |

| 24,109.27 | 14,180.32 | 10,032.03 | 23,929.20 | 13,954.51 | 9,974.70 | |

Waste diverted from disposal

|

Onsite MT |

Offsite MT |

Total MT |

|

| Hazardous waste | |||

| Preparation for reuse | – | 26.63 | 26.63 |

| Recycling | – | 56.99 | 56.99 |

| Other | – | – | – |

| Total | – | – | 83.62 |

| Non-hazardous waste | |||

| Preparation for reuse | – | 4,457.46 | 4,457.46 |

| Recycling | – | 9,413.41 | 9,413.41 |

| Other | – | – | – |

| Total | – | – | 13,870.87 |

| Waste prevented | – | – | 13,954.49 |

- Hazardous waste – Solid chemical waste, contaminated fabric, silicon glue, sludge, empty hazardous containers, contaminated packaging, E-waste, tube light, liquid chemical, waste oil

- Non-hazardous non RM waste – Paper, cardboard, polyethene, food, regiform, wood and wood pellets, glass waste, municipal waste

- Non-hazardous RM waste – Fabric, foam, garments, plastic thread cone, mixed waste, elastic, BPU, fabric dust, expired yarn, right-off

Waste directed to disposal

|

Onsite MT |

Offsite MT |

Total MT |

|

| Hazardous waste | |||

| Incineration with energy recovery | – | 916.01 | 916.01 |

| Sanitary landfilling* | – | 0.92 | 0.92 |

| Other | – | – | – |

| Total | – | – | 916.93 |

| Non-hazardous waste | |||

| Incineration with energy recovery | 3,588.21 | 5,230.48 | 8,818.69 |

| Sanitary land filling** | – | 34.91 | 34.91 |

| Other – dried STP sludge (land application as fertilizer) | – | – | 8.48 |

| Other-ash (land application as fertilizer) | – | 195.71 | 195.71 |

| Total | – | – | 9,057.79 |

*0.92 MT sent to sanitary landfill comprise of the glass wool sent to sanitary landfill from Texo facility renovation. This process was approved and authorised by the Central Environmental Authority and carried out under the supervision of them.

**34.91 MT Sent to sanitary landfill comprise of mixed fabric waste generated from MAS Kenya operations where the waste is diverted to the sanitary landfill due to lack of waste energy recovery/co processing solutions. Currently the facility is working towards a minimising this waste category and co-processing solution.

Innovation for Effluent Treatment and Management – LINEA AQUA

The previous Sewage Treatment Plant (STP) sludge, consisting of about 80% water, was dewatered using a vertical sand-bed filtration system. This method was both time-consuming and resource-intensive, requiring recurrent water removal by browser.

The Maintenance department of LINEA AQUA Hanwella, brainstorming with other teams, proposed and promptly initiated replacement of the vertical sand-bed with horizontal filtering tanks. This new initiative to dewater Sludge effluent was not only more cost-effective, but also resulted in a host of environmental benefits, efficiency gains, and cost-savings.

- Sludge volumes reduced by 24,000 litres per week

- Cost saving of LKR 5 Mn. per annum

- Enabled 70% internal water reuse for other operations

- Lowered water intake and overall CO2 emissions

Successful implementation of this process shift was recognised with a bronze at the 2023 Future Stars Awards.

Going Zero Waste – MAS SILUETA

R2 Project:

Re-Purposing Waste

As part of our efforts to add value to waste, facility-level teams have pioneered the use of fabric waste, foam waste, and polythene to develop a variety of new and innovative products. The initiative currently produces items such as cartons, partitions, separators, paper books, calendars, soundproofing panels, holders, ceiling sheets, files, mousepads, and storage or packaging boxes.

Innovations to Upcycle Fabric Waste

The MAS Brand Protection Unit (BPU) receives excess written-off fabric from plants each month, and aims to give this fabric a second life. The Unit carries out a Reconsolidating and Broadcasting (R&B) Project wherein excess written-off fabric is upcycled for use within MAS by in-house design teams, to support small and medium entrepreneurs, and to manufacture products for sales at an internal boutique for MAS employees to purchase.

Fabric received is segregated according to category needs and upcycled in fabric and finished-good form. By doing so, the BPU reduces excess production of both Raw Materials and Finished Goods. In 2024, the Unit upcycled over 22,000 kg of fabric, equating to a water-saving of 830,000m3 and an emission-saving of 222,000 kgCO2e.

Looking to 2025/26, our strategies will continue to focus on expanding textile-to-textile recycling across more fabric types through active collaboration with solution providers and ongoing trials. In addition, we will continue to minimise waste generation itself, through continuous improvement projects and circular economy initiatives aimed at greater resource recovery and reduced environmental impact. We expect that our continuous work with fabric recyclers, incorporation of new technology, and validation of further commercial use-cases for waste valorisation will result in positive progress in the years ahead.

Waste management and circularity

Driven by our vision to pioneer circularity at scale, we made significant progress towards the Company’s internal circularity targets that aim to reintroduce post-industrial raw material waste back into the production cycle. This includes fabric, yarn, foam, and any raw material used in manufacturing – introduced back into the apparel and textile industry through either chemical or mechanical recycling to a higher or lower-value material. Reintroduction can occur within MAS’s own textile and apparel manufacturing for new products or by supplying these reclaimed materials as raw materials to external textile and apparel product manufacturers.

Circularity through Textile-to-Textile (T2T) Recycling

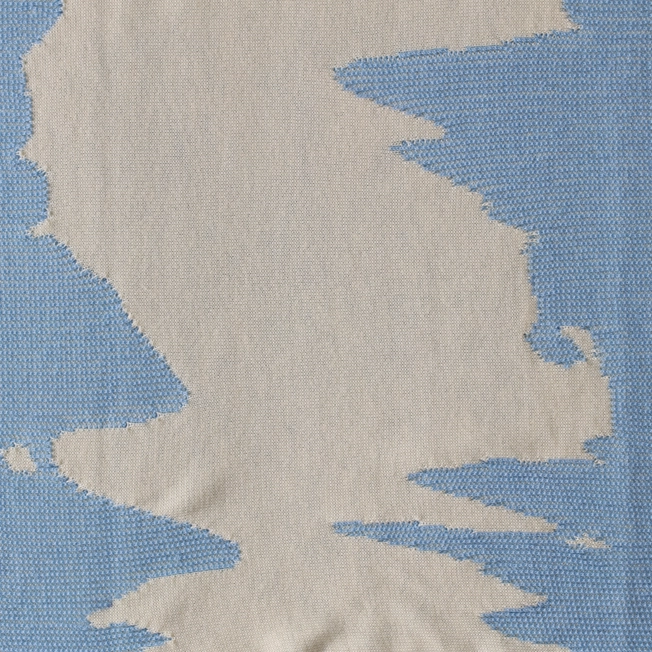

We broke new ground in 2024, engaging with textile-to-textile recycling technology providers to pilot commercial-level Initiatives for high-cotton-content fabrics (e.g. 100% and 95% cotton), for which viable recycling solutions are already available.

Closed-loop T2T recycling plays an important role in the circular economy by reducing the demand for virgin materials, retaining materials within the textile and apparel ecosystem, and enabling multiple life-cycles for raw material inputs; all while maintaining high levels of traceability.

The Central Sustainability Team worked to proactively identify end-users and verify the diversion of fabric waste into T2T recycling streams. Successful implementations in 2024 included mechanically recycled cotton, for manufacturing of socks and home-furnishing textiles, which led to a verified 10.64% diversion rate for fabric waste to T2T recycling within the Group.

Waste reduction projects, such as paperless workspaces and processes, and cutting table efficiency improvements also continued to net positive results, as did our ongoing food-waste reduction initiatives. Maintenance of point-wise waste segregation and designated waste stations/yards, coupled with bi-annual trainings for our waste handling teams was instrumental in ensuring success. In addition, we continued to work with carefully selected and regularly assessed third-party partners for treatment and disposal.

Responsible Chemical Use

GRI 303-1 and 303-2

Practicing responsible chemical management in the apparel industry gives us the means to minimise harm and maximise positive impact – to achieve far-reaching benefits for employees, consumers, and environment.

Our goal, to be zero toxic in products and processes, involves a commitment to green chemistry practices and a continuous journey to study chemical impacts, incorporate regulatory requirements, uphold industry best practices, and meet consumer expectations.

To this end, we are actively streamlining chemical management within our facilities, implementing robust procurement controls, forging collaborative partnerships with chemical suppliers, and upholding transparency through rigorous verification and certification.

We made significant progress in 2024, strengthening responsible chemical use across our operations and supply chain by focusing on rigorous input standards, process controls, and output compliance; ensuring alignment with stringent environmental and safety standards.

Our dye and embellishment facilities achieved 96% compliance with ZDHC MRSL version 3.1 level or above conformance against performance InCheck criteria, up from 88% the previous year, as we caried out internal testing of chemicals for version 3.1, replaced non-compliant products with compliant alternatives, and actively engaged with chemical suppliers for updated chemical testing against the new ZDHC MRSL version 3.1 that was fully implemented by November 2023.

Dye facilities demonstrated outstanding input compliance in 2024 – achieving 100% alignment with ZDHC MRSL version 3.1 level 1 or above conformance against performance InCheck criteria (98% in 2023), and utilising 95.4% Bluesign approved chemicals (94% in 2023). Embellishment facilities made strong progress in input compliance, reaching 91% conformance against InCheck criteria in 2024, up from 75% in 2023. We also completed the year with no incidents of non-compliance with ZDHC wastewater discharge limits.

All subcontractors achieved minimum 81% compliance with ZDHC MRSL Version 3.1 whilst three subcontracting facilities achieving 100% compliance. We also continued monitoring of input chemical compliance and ZDHC wastewater compliance for 55% of our spend base, up from 42% in 2023.

In 2024, we extended our monitoring of Tier 1 suppliers supplying wet raw materials, to vendors comprising the top 90% of our spend-base (80% in 2023). Similarly, in terms of wet operations, we increased screening to cover 62% of our spend-base who had generated ClearStream reports through the ZDHC Gateway (43% in 2023).

Responsible Chemistry within our Facilities

In 2024, we updated the

MAS RSL Manual – Version 3.0. In addition to alignment with the RSL Manual, MAS has

obtained 16 OEKO-TEX Standard 100 certificates, covering 22

facilities across the Group. As part of our commitment to

implementing sustainable chemical management across our

operational footprint, 22 MAS facilities completed Level 1

self-assessment, and one facility reached level 2 in the ZDHC

Supplier to Zero certification programme.

Over the course of the year, we conducted around 100 RSL tests meeting customer-specific requirements; additional individual tests for bisphenol, formaldehyde and phenol bases; and nine randomised RSL tests for key suppliers across the value chain.

Our Bluesign Commitment

In 2022, we began alignment of our chemical management with Bluesign – one of the most stringent global sustainable chemical certifications. As of 2024, MAS Fabrics Private Limited – Intimo Division remains a Bluesign System Partner delivering Bluesign certified articles, and two additional facilities have been onboarded in obtaining Bluesign system partnership. Recognising our commitment to sustainable Textile Production, MAS Fabrics Private Limited – Intimo Division was awarded the Bluesign Appreciation Award in 2024.

Dye Facility SOPs for chemical procurement, aligned with the MAS Chemical Management Manual, mandate the use of Bluesign dyes and auxiliaries for dyeing operations Succes in this regard saw our Dye Facilities enhance compliance in 2024; achieving 95.4% Bluesign approved chemicals within 2024.

To support mainstreaming of this commitment, we conducted staff training that included awareness on Bluesign standards, assessed the latest updated version of Bluesign Black Limits for threshold limits, standards and guidance to inform our processes. We prioritised sourcing of low-risk Bluesign-approved chemicals, and continued to continue to encourage the use of Bluesign-approved chemicals in all inputs and in-house chemicals.

Continuing to enhance chemical management competence across our workforce, we conducted comprehensive training programmes at all levels, and specialised sessions for executive staff on RSL, ZDHC MRSL, Bluesign, and internal chemical management policies. To further deepen expertise, executive staff received in-depth ZDHC CMS TIG training, resulting in certification for 45 participants.

Innovation for Chemical Management Excellence

In 2024, we introduced chemical replacements and treatment cycle optimisations at some of our facilities that led to reduction in the Mass to Liquor Ratio (MLR). Reductions to MLR are hard-won gains in our industry; leading to cost-savings and process efficiencies, reduced water and chemical consumption, lowering overall energy costs, and lessening risk and impacts associated with wastewater treatment and discharge.

Other projects for responsible chemical management and sustainability, founded on green chemistry principles, included hot water recovery from dye baths, dye recipe optimisations using TDS, and the use of natural dyes and non-curing pigments.

One of our facilities achieved a water savings of 11,800 m³ by introducing a new chemical series that reduced the cycle time from 11 hours to 7 hours and improved the MLR from 1:12to 1:8, with another facility saving 47,700 m³ of water by optimizing the MLR from 1:15 to 1:10. Additionally, two facilities collectively saved 18,700 m³ through effective hot water recovery initiatives.

Chemical compliance across the supply chain

For suppliers of fabrics, apparel embellishments, or chemicals, the risk of hazardous chemicals in products are controlled through ZDHC MRSL compliance assessment. We engage and work with all major raw material suppliers and monitor input chemicals for approximately 55% of our spend-base against the ZDHC MRSL (42% in 2023).

Further RSL testing is also carried out for products and materials, if mandated by specific customer brands. Brand-specific RSL requirements are also cascaded to vendors and supply chain partners, and their confirmations, acknowledgements, and self-assessments enable compliance with the same. Whereas 62% of spend base generated ClearStream reports via the ZDHC Gateway. By year-end, 82% of raw material suppliers by spend base were onboarded to the Higg FEM platform (75% in 2023).

Similarly, we ensure subcontractors are monitored against ZDHC MRSL in their production process, which serves to restrict most chemicals of concern and meet brand-specific requirements. All subcontracting facilities achieved a minimum of 81% compliance, with three reaching full 100% compliance and are encouraged to use 100% ZDHC MRSL-approved chemicals in production. Further all subcontractor facilities were monitored for completion of verified Higg FEM and wastewater testing against ZDHC wastewater guideline. All eligible subcontractor facilities were aligned with ZDHC WWG requirements for wastewater. Annual subcontractor forums are a key tool in raising awareness, communicating expectations, and ensuring compliance; while interim meetings serve as a monitoring tool to evaluate compliance and progress toward targets. When failures are found, or chemicals of concern likely to be regulated are identified, we work collaboratively with subcontractors to find safer alternatives.

Champion Biodiversity

GRI 304-1, 304-2, 304-3

The apparel industry, with its extensive global supply chains and reliance on natural resources, bears a profound responsibility in biodiversity conservation. Acknowledging the impact of our operations on biodiversity, we actively contribute to its conservation and restoration; working towards an ambitious pledge to restore habitats and enhance ecosystem services in an area 100 times larger than our physical footprint.

Read about our model for

biodiversity conservation

and project prioritisation in our areas of operation.

A key achievement for the year was the extension of our conservation footprint by 7,223 acres; including expansion of the Kenya Conservation project, Indonesia Reforestation project, and Minuwanella Reforestation project; restoration project in Rambapokuna and a new mangrove restoration project in Trincomalee.

This substantial scaling-up of biodiversity conservation efforts has enabled us to reach 79% of our 2025-target, with a cumulative area of 19,927.48 acres restored or conserved, including 1,561 acres verified by third-party professionals.

During the year 2024 we continued to lend support to a variety of ongoing projects including Leopard Conservation in Eastern Sinharaja; invasive-removal at the Horton Plains National Park; reforestation in Minuwanella; the Knuckles Reforestation Project; Rambapokuna Reforestation project; and Mangrove Restoration in Trincomalee. Additionally, we successfully completed a two-year, 12.5-acre, mangrove restoration in Kepuella, Galle – on Sri Lanka’s southern coastline.

Our largest project to date – the Kenya Conservation Project also saw expansion in 2024. The project area increased by 930 acres to reach a total extent of 8,275 acres by the end of the year. Similarly, the Blora-Ngawi Biodiversity Restoration Project in Central Java, Indonesia also saw a significant increase in restored acreage – encompassing a project area of 7,470 acres across 2023 and 2024.

BIODIVERSITY CONSERVATION ANNUAL ACHIEVEMENT

CUMULATIVE BIODIVERSITY CONSERVATION PROGRESS

BIODIVERSITY PROJECTS BY ACREAGE

As we work toward reaching our biodiversity goal for 2025, our achievements hinge on strengthening ongoing partnerships with government, non-profits, academic institutions, and community organisations; which enhance the scope, sustainability, and effectiveness of all our conservation initiatives.

Biodiversity conservation in action: success stories

Conservation

Our in-situ conservation projects are working to preserve biodiversity, safeguard natural ecosystems, and protect a species threatened by habitat-loss, human-animal conflict, and other anthropogenic impacts. We work with pioneering partners and promote holistic and innovative approaches to conservation that can have a lasting impact.

By the end of 2024, our completed and ongoing Conservation projects encompassed 8,428.69 acres, representing approximately 42% of our total achievement by area.

Our Kenya Conservation Project, at the Nairobi National Park Wildlife Dispersal Area, saw further development in 2024. The target area was expanded by 930 acres, bringing the total project area up to 8,275 acres. This ongoing project has a lofty but impactful ambition – to establish secure areas for wildlife and local communities by promoting community conservation, conservation easements, and wildlife conservation leases outside Kenya’s Protected Area and Reserves.

Panama In-Situ Turtle Conservation Project

Location: Panama, Sri Lanka

Conservation Area: 10 Acres, 3km Beach stretch

Project Partners: MAS Intimates, DIMO, Commercial Bank, Wildlife and Ocean Resources Conservation Society Ampara

Multiple species of endangered or critically endangered sea turtles have been known to use Sri Lanka’s coastline as a nesting ground. These majestic creatures, already under pressure due to ocean pollution and climate change, also face threats on land, particularly during their nesting season, which can have a significant negative impact on species survival rates.

Three of Sri Lanka’s best-known corporates came together to address this critical issue, partnering with a local environmental organisation – Wildlife and Ocean Resources Conservation Society. The project focuses on a 3km 10 acres stretch of beach extending from Kunukala Lagoon to Beedi Modara. This area is part of a longer 17 km stretch that is a well-known nesting hotspot for sea turtles from October through May.

From October 2023 to June 2024, the project successfully protected 272 turtle nests that would otherwise have been lost to human interference or natural predation. Safeguarding these nests in-situ, minimised disturbance to the natural incubation process and retained original nesting locations where parents could return in future years. Following the natural incubation period, over 17,000 turtle hatchlings were safely released into the ocean.

Such urgent and direct interventions by responsible corporations can dramatically increase the survival rate of new turtle generations, and contributing significantly to the conservation of these globally vulnerable species.

Restoration

Our restoration projects aim to initiate, support, or accelerate recovery of disturbed ecosystems, and strengthen the communities and institutions that function as their environmental stewards. Restoration methods vary from efficient and cost-effective aerial restoration for heavily degraded areas; to resource-intensive multistage methodologies such as replanting, community engagement, public awareness and education, and collaboration with local counterparts to develop and operationalise comprehensive conservation plans. As at the end of 2024, our Restoration projects, both completed and ongoing, span 8,327.5 acres and account for about 42% of our project achievement by acreage.

Blora Ngawi Biodiversity Restoration Project

Location: Central Java, Indonesia

Restoration Area: 7,470 acres (2023-2024)

Project Partners: PT. Pesona Indonesia Tours, Universitas Gadjah Mada, MAS Partners, MAS Capital, MAS KREEDA, MAS Intimates, Silueta, MAS Active, Bodyline, Noyon, Trischel, Prym Intimates

In 2023, we launched our second largest biodiversity project in terms of acreage, at Indonesia’s Central Java region, known for its rich biodiversity. One year in, the Blora Ngawi Biodiversity Restoration Project has successfully restored 7,470 acres of land; a significant re-establishment of healthy forest landscapes and building of ecosystem resilience.

The project’s objectives focus on holistic environmental stewardship:

- Developing a multi-stakeholder forest management model encompassing forest protection, development, land rehabilitation, and animal habitat enrichment.

- Improving the quality of wildlife habitat through ecosystem restoration and the protection of critical areas.

- Increasing wildlife populations in KHDTK Getas by expanding adequate habitat and enhancing protection efforts.

To achieve these goals, a meticulous and community-centric approach was adopted. Land preparation involved detailed planning and execution by local residents, ensuring ecological sensitivity and providing stable employment.

Over 527,460 trees from diverse species, including Coffee, Moringo oleifera, Indigofera, Senna siamea, Gliricidia sepium, Erythrina variegata, and Leucaena leucocephala, were strategically planted. This scale of tree-planting significantly contributes to the restoration of vital habitat for wildlife, and supports the long-term health of the ecosystem. The collaborative framework between MAS, Universitas Gadjah Mada, and PT. Pesona Indonesia Tours is a strong indicator of the potential for multi-stakeholder projects to achieve sustainable conservation outcomes at massive scale.

Ittapana Mangrove Forest Restoration Project

Location: Bentota, Sri Lanka

Project Area: 1 acre

Planted Species: Bruguiera gymnorhiza, Bruguiera cylindrica, Cerbera manghas, Sonneratia alba Project Partners: Linea Aqua (Pvt) Ltd, Center for sustainability University of Sri Jayawardenapura Sri Lanka’s mangroves play a vital role in the health and resilience of the island-nation’s coastal and riparian ecosystems. Mangrove forests are unique intertidal ecosystems that are critical for biodiversity, coastal and riverbank protection, and the livelihoods of local communities. They serve as nurseries for fish and shellfish, provide nesting sites for birds, and act as natural barriers against erosion.

Recognising their immense ecological and socio-economic value, the Ittapana Mangrove Forest Restoration Project was launched in 2023 to rehabilitate a degraded one-acre site within the Ittapana Mangrove Conservation Forest in Bentota.

Core objectives of the project included:

- Restoring degraded land to a healthy ecological balance.

- Addressing environmental degradation from saltwater intrusion and unsustainable anthropogenic activities.

- Re-establishing thriving mangrove ecosystems to boost biodiversity, prevent erosion, and enhance carbon sequestration.

- Raising awareness and delivering tangible benefits to local communities and other target groups.

By the end of 2024, the project has successfully planted 500 mangrove saplings from key species, achieving an impressive 94% survival rate. The project also completed a number of critical steps for long-term ecosystem health, including the clearing of invasive species, establishment of a 25-ft buffer zone, and construction of drainage canals to optimise saltwater levels.

The project has also contributed a number of direct and indirect benefits to the community, including:

- Restoration of crucial fish nurseries, supporting local fisheries and potential ecotourism.

- Enhanced water purification and retention, beneficial for local agriculture.

- Reduced risks of coastal erosion and storm damage, protecting coastal communities.

- Opportunities for economic benefits through sustainable use of revitalised mangrove resources.

Community involvement has been at the heart of the project’s success. Local residents established and managed two community nurseries, participated in comprehensive training on mangrove care, and actively engaged in site clearing, planting, and ongoing maintenance. University students also provided invaluable support with GPS mapping and data collection.

The project also facilitated numerous education and awareness sessions for university students, international school groups, and foreign delegates. University-led research is now underway to propagate Kirala (Sonneratia alba) plants, to develop the Ittapana Mangroves into a hub for continued restoration and further knowledge sharing.

Invasive removal and habitat enrichment

Our projects respond to Invasive Alien Species (IAS) that are disrupting areas of high biodiversity value such as national parks, which are often home to a number of endemic, endangered, vulnerable, or threatened species. We work with partners to carry out programmes for targeted removal of invasive species, long-term maintenance and restoration of natural vegetation, and enrichment planting that supports restoration of ecological balance.

Since 2017, we have carried out IAS-removal and habitat enrichment projects across 3,092.08 acres, spanning seven of Sri Lanka’s protected conservation areas, and accounting for around 15% of our total conservation achievement by acreage.

Removal of Invasive Alien Species – Ulex europaeus

Location: Horton Plains National Park, Sri Lanka

Conservation Area: 244 acres

Project partners: Federation of Environmental Organisations (FEO), Department of Wildlife Conservation (DWC), MAS Intimates, Linea Aqua,Trischel and Prym Intimates

Target Invasive Species:

Ulex europaeus

Horton Plains National Park is a UNESCO World Heritage Site in the central highlands of Sri Lanka. It is a unique montane ecosystem characterised by cloud forests, grasslands, and exceptional biodiversity, including endemic flora and fauna. However, this fragile ecosystem faces significant threats from Invasive Alien Plant Species (IAPS), particularly Ulex europaeus, which has spready rapidly, threatening the park’s ecological integrity and the survival of its unique species, including endemic grazing herbivores like the Sambar.

In 2023, MAS partnered with the Federation of Environmental Organisations (FEO) and the Department of Wildlife Conservation (DWC) to address the threat of Ulex europaeus. The main objectives of this initiative are twofold: to remove IAPS prior to seed generation – preventing further spread and facilitating the growth of native varieties; and to involve workers from surrounding communities – fostering local ownership and providing them with stable income.

By the end of 2024, we can report significant progress - including completion of the first round of Ulex europaeus removal for over 82% of the identified areas. This remarkable achievement was completed ahead of schedule; testament to the dedication of field associates and local community workers, and their understanding of the project’s rationale and urgency. The commitment of local workers, who receive regular employment through the initiative, has been instrumental in accelerating the removal process. Phase 2 will commence following the same sequential order as the initial clearance, ensuring that any Ulex re-growth is addressed swiftly before it can flower and spread.

Beyond direct ecological impact, the project has catalysed invaluable relationships and mutual learning. The DWC team deployed to Horton Plains National Park has worked collaboratively with FEO, enabling and extending the reach of both organisations. An exemplar has been broader community engagement through the ENVFORCE Youth Alliance, and FEO’s local projects with schools located in Dayagama; where project teams raise awareness on conservation, biodiversity, and the importance of coexistence.

Quantifying our impact

Despite the inherent complexity of biodiversity conservation, which poses challenges to impact measurement and outcome tracking, we are dedicated to quantifying our impact to assess effectiveness, identify areas for improvement, and refine future strategies.

Research on the Sri Lankan Leopard and Human-Wildlife Conflict (HWC)

Location: Eastern Range, Sinharaja World Heritage Site, Sri Lanka

Project Duration: 5-year study/ highlight, commenced in 2022 (ongoing)

Project Partners: Wildlife Conservation Society Galle, MAS Intimates

Resource Persons: Supun Deshaprema, Madura De Silva, Sisira Darshana

Our commitment to preserving biodiversity and conserving Sri Lanka’s last virgin rainforest, goes as far back as 2017, with eight conservation projects carried out to-date. In 2022, partnering with the Galle Conservation Society, MAS initiated its first single-species conservation project - focused on the Sri Lankan leopard population in Eastern Sinharaja.

The Sri Lankan leopard (Panthera pardus kotiya), classified as an Endangered species (EN), is widely recognised as the sole apex terrestrial predator in Sri Lanka. While significant research has focused on leopard populations in the dry-zone, scientific understanding of their wet-zone counterparts, particularly in fragmented forest ecosystems, remains limited. The Sinharaja World Heritage Site, a UNESCO Natural World Heritage site and a global biodiversity hotspot, represents one such critical wet-zone habitat. Despite their protected status and presence within a national forest reserve, increasing territorial overlap with human settlements, particularly tea estates in the region, has led to a rise in Human-Wildlife Conflict (HWC); which is posing a significant threat to leopard populations and human livelihoods.

As part of our Leopard Conservation Project, a team of well-known researchers are conducting a longitudinal study to identify the possible reasons for human-leopard conflict in the southwestern wet-zone and propose measures that would result in mitigating the problem; using Eastern Sinharaja as a study area. The team is monitoring leopard behaviour in an anthropogenic landscape, and also studying decades-worth of data on human-leopard encounters in the area to identify HWC hotspots. Other objectives of the project include:

- Estimating the density of leopard populations in forest patches associated with tea estates where human-leopard encounters are high.

- Assessing prey densities and diet preferences of leopards, testing two hypotheses: (i) that leopards are drawn to estates due to a lack of food in their natural habitat, and (ii) due to a preference for easy prey.

- Gathering perspectives of the stakeholders from the estate sector; on leopards and the possibility of human-leopard coexistence.

As part of the ongoing study, research findings are already shedding light on this elusive predator and improving overall knowledge on the challenging topic of HWC.

Throughout the five-year period, 396 leopard scat samples have been meticulously collected and analysed to identify prey species. Samples were categorized based on their aerial distance from the forest boundary to assess dietary variations.

Dietary Preferences: Analyses revealed that 35.85% of scat samples contained bone particles of Sambar (Rusa unicolor), indicating that Sambar is a preferred prey species for leopards in the Eastern Sinharaja range.

Triggering Factors for Conflict: A considerable percentage of scat samples contained bone particles of domestic dogs, highlighting a significant contributing factor to human-leopard conflict. This suggests that leopards may be preying on domestic animals, potentially due to proximity to human settlements.

Habitat Preference, Triggers, and Potential HWC Hotspots: Direct and indirect evidence collected during the study indicates that leopards prefer forest margins, grasslands, or marshy areas over dense forest interiors. This finding is crucial as these preferred habitats often border human-dominated landscapes, increasing the likelihood of encounters.

Based on ongoing research and identified conflict drivers, several proactive conservation actions have already been integrated with the project for implementation:

- Education and awareness for tea plantation management, staff, and workers on the importance of leopard protection has been a key initiative. Similar education programmes have been conducted for schools in the study area.

- Regular removal of snares around the borders of the Eastern Sinharaja area is being developed carried out with the active participation of tea plantation workers, cardamom pluckers, and voluntary groups. Snares are a major cause of accidental leopard mortality and injury in these transitional zones. Further, collection of motorbike and three-wheel brake and clutch cables from local sources aims to prevent these materials from being repurposed into snares by hunters.

- Mapping and listing individuals who own cattle and goats around identified red zones (areas marked as high-risk for leopard attacks on livestock) is underway. This will support targeted engagement in the future.

Impact of Mangrove Restoration

Location: Sambaltheevu Lagoon, Trincomalee, Sri Lanka

Area Conserved: 10 acres

Planted Species: Avicennia sp. and Rhizophora sp.

Project Partners: Department of Forest Conservation, MAS Capital

Research partners: University of Colombo, University of Kelaniya

Since 2023, MAS has partnered with the Department of Forest Conservation to undertake a vital mangrove reforestation project. In 2024, to ensure scientific rigor and contribute to the long-term success of our restoration efforts, we worked with a research team led by prominent academics from the University of Colombo and University of Kelaniya.

The research project focused on assessing the survival rate and growth performance of planted Rhizophora mucronata seedlings, evaluating the impact of environmental factors on seedling survival and growth. Analysis from the research team would also support documentation of associated fauna and flora in the area and predicting the carbon sequestration impact of restoration.

Just nine months from project inception, our initial findings are highly encouraging:

High Survival Rate: Healthy restoration of Rhizophora mucronata was observed with an impressive 80.88% survival rate, indicating the suitability of planting techniques and site selection.

Natural Regeneration: Significantly, Avicennia marina was found to be regenerating naturally at the restoration site alongside the planted Rhizophora mucronata.

Environmental Influences: Environmental factors such as salinity, tidal influence, and herbivory by terrestrial animals were identified as key factors affecting the survival and growth of Rhizophora mucronata seedlings. This understanding is crucial for refining future restoration strategies.

Carbon Sequestration Potential: Early projections indicate that after 15 years, the restoration site will sequester approximately 4.822 tonnes of carbon per hectare per year after.

Impact of Invasive Removal

Location: Bundala National Park, Sri Lanka

Area Conserved: 844.76 acres

Target Invasive Species: Prosopis juliflora

Project Partners: Department of Wild Life Conservation, Department of Wild Life Conservation, Linea Aqua, Bodyline, Noyon, MAS Capital, Trischel

Bundala National Park, a Ramsar wetland and a UNESCO Biosphere Reserve, is a critical habitat for a diverse range of flora and fauna - particularly as a wintering ground for migratory waterbirds. However, like many protected areas globally, Bundala has faced significant threats from Invasive Alien Species (IAS), with Prosopis juliflora being a dominant concern. Prosopis juliflora is a highly aggressive, fast-growing thorny shrub that forms dense, impenetrable thickets. Its rapid spread displaces native vegetation, reduces grazing lands, alters soil chemistry, and negatively impacts water availability, thereby threatening the park’s delicate ecosystem balance and the biodiversity it supports.

Following our IAS-removal project at Bundala, conducted between 2018 and 2022, we commissioned an impact assessment to study the effectiveness of our conservation efforts and add to body of knowledge on understanding and mitigating the ecological impacts of Prosopis juliflora.

The assessment sought to assess how faunal and floral diversity was affected by the invasive removal, to determine if invasive removal directly supports herbivore populations within the Park, and to assess the status of other invasive species in areas where Prosopis juliflora has been removed.

Our initial assessment following the Prosopis juliflora removal yielded promising insights:

Faunal and Floral Diversity: While further confirmation through additional field visits is needed, preliminary data suggests a non-significant but higher diversity of both butterflies and birds in the cleared areas; compared to uncleared control areas. This hints at a positive trend towards ecosystem recovery and increased ecological-niche availability for the Park’s native residents and migrants.

Support for Herbivores: A significant positive outcome was observed, with increased grass cover in cleared areas, which was twice that in non-cleared areas. This directly supports and enhances the habitats for herbivores, providing crucial forage and potentially leading to an increase in their populations.

Status of Other Invasive Species: Eupatorium odoratum and Lantana camara were observed in both cleared and non-cleared areas, with a higher abundance of Lantana camara noted in cleared areas. This highlights a critical challenge that requires addressing.

Safeguard Water

GRI 303-3, 303-4

Water is a vital resource across the apparel value chain – from raw material inputs, to manufacturing processes, and the aesthetics and functionality of finished products. In a world where escalating population growth, human development, and climate-change induced shifts are increasing the strain on our planet’s vital water resources, the apparel industry faces a unique imperative.

Recognising this challenge, MAS embeds water stewardship as a core business strategy; actioned through collaborative efforts with customers, partners, suppliers, and communities; investment in the capabilities, awareness, and engagement of teams; and continuous improvement of technologies and processes.

Achieve zero impact to MAS’ operations and mitigate negative impact to the environment and community.

*based on 2011 baseline

In 2024, overall water efficiency showed continued progress toward our 2025-target, reflecting an aggregated 50% water intensity reduction against the 2011 baseline. This is a 12% reduction in water intensities of our Textile Production operations and 7% reduction in water intensity of our Apparel Manufacturing operations, against the previous year.

Our ongoing initiatives for water conservation, in the form of daily water-meter monitoring and balancing, installation of water-efficient fittings with adjusted flow-rates that are compliant with MAS internal standards and international best-practices, regular meter verification, proactive leak detection, and employee awareness programmes; all contributed to reducing our water-intensity.

Our water footprint

GRI 303-5

Total water withdrawal amounted to 2,590.04 ml in 2024. The majority of our water, almost 83%, comes from third-party sources. Groundwater usage for the year stood at 271.81 ml. Water withdrawal is equal to the water consumption as at 31 of December 2024.

In 2024, we adopted the TEXO facility as a cotton mill falling within the Group’s operational and reporting boundary. Thus, moving forward, it will also be included in the intensity reduction calculations. In 2024, the resulting addition to our water intensity calculations was 155.98 litres per kilogram.

Textile Production accounted for approximately 48% of the Group’s water use, while Apparel Manufacturing accounted for roughly 52%. This distribution is largely unchanged year-on-year, while volume of water-demand is directly associated with production volumes and scale of our operations.

| 2019 | 2020 | 2021 | 2022 | 2023 | 2024 | |

| Groundwater (ml) | 334.9 | 246.91 | 293.21 | 297.87 | 258.26 | 271.81 |

| Third-party water (ml) | 1,629.33 | 1,446.86 | 1,810.68 | 2,238.42 | 1,574.29 | 2,318.24 |

| Total water withdrawal (ml) | 1,964.28 | 1,693.77 | 2,103.89 | 2,536.30 | 1,832.55 | 2,590.04 |

| Rainwater (ml) | 2.17 | 11.57 | ||||

| Recycled water (ml) | 94.90 | 197.76 | ||||

| Gross water-demand/water footprint (ml) | 1,929.62 | 2,799.38 | ||||

Sustainable water management at MAS

We continued efforts to reduce reliance on freshwater sources by scaling up use rainwater harvesting and wastewater recycling. The volume of water recycled more than doubled, year-on-year, reaching 197.76 ml. Recycled water now meets 7% of our total water demand for the year.

Rainwater harvesting yielded 11.57 ml in 2024; with the effects of seasonal and climatic variance, this water-source currently meets less than 0.41% of our water-demand for the year. Water recycling at our Sewage Treatment Plants (STPs) amounted to 197.76 ml, for the year. This recycled water is used for gardening and landscaping at the majority of our facilities. One of our facilities carries out further multi-stage treatment for wastewater, including Reverse-Osmosis (RO), enabling recycled water at the facility to be used as input water for flushing and in cooling towers.

Working to reduce water intensity of our industrial processes, we implemented a variety of mini-projects across our dye houses, including measures to optimise material-to-liquor ratio and processes for reuse of hot water drained from the dyeing operations.

Protecting Catchment Areas and Aquatic Ecosystems

Kalu Ganga and Karasnagala watershed, Sri Lanka

Bodyline launched a landmark sustainability initiative in collaboration with the Government of Sri Lanka and the Ministry of Environment; planted over 2,000 trees along the Banks of the Kalu Ganga.

The project also united over 250 Bodyline volunteers, who contributed more than 1,000 volunteer-hours, as they worked alongside local communities to set up and ensure long-term care of the newly planted trees. Additionally, we partnered with MAS Eco Go Beyond (EGB) project students, instilling in them a lasting sense of responsibility toward environmental conservation. This structured care and maintenance plan ensures the long-term survival of the trees through dedicated support from responsible stakeholders.

Sri Lanka’s Kalu Ganga directly supports over 800,000 local residents, including a large number of MAS employees from the Thalahitiya-Yatawara area - which was chosen for the project implementation. While the project sought to enhance their and preserve the region’s rich ecosystem, an intentional additional benefit of the project was to strengthen the natural buffer along the riverbank; effectively mitigating flooding risks and improving the resilience of both our employees and the broader community.

MAS KREEDA Campus completed a similar project during the year, working to enhance the ecosystem quality of water catchment areas at the Karasnagala watershed region; planting 400 Kumbuk (Terminalia arjuna) and Mee trees (Madhuca longifolia) , in collaboration with Sri Lanka’s Water and Drainage Board, local communities, and school children from the area.

The local Kumbuk tree species was selected for these projects due to its significant environmental benefits. It plays a crucial role in water purification and flood risk mitigation. With its deep root system, Kumbuk stabilises riverbanks, preventing soil erosion and reducing sedimentation in waterways. Acting as a natural filter, it also helps absorb pollutants and improve water quality. Additionally, Kumbuk trees regulate water flow by absorbing excess rainwater, reducing surface runoff, and minimising the risk of floods.

Community-Focused Water Initiatives

Kalpitiya and Anuradhapura Districts, Sri Lanka

Anuradhapura Pooja Bhoomiya is one of Sri Lanka’s most significant religious and cultural sites, drawing hundreds of thousands of pilgrims and tourists each day. On average, between 200,000 to 250,000 people visit the site, with numbers surging during special religious events and holidays.

However, despite the site’s importance, there was a significant challenge: a shortage of clean drinking water for many visitors. Local raw-water resources had particularly high levels of hardness, making it unsuitable for safe consumption without suitable purification.

Existing water supply systems included a Reverse-Osmosis (RO) water purification plant, capable of processing 10,000 litres of water per day. The plant was installed and maintained by the Sri Lanka Navy, but even with this facility, the demand for clean water far exceeded its capacity.

Recognising the urgent need for safe drinking water, Bodyline stepped in to install an additional RO plant capable of processing 15,000 liters of water per day. Once commissioned, this would more supplement the existing system, effectively doubling the capacity and provide adequate purified water to meet the demands of visitors. To further improve accessibility, drinking water tap-basins were also set up at high-traffic areas between the road leading to Jaya Sri Maha Bodhiya and Ruwanweliseya – a path used by nearly all the visitors to the area.

A similar Community Water Project in Kalpitiya was implemented through a collaborative effort between the Sri Lanka Air Force, MAS Capital, and Bodyline. Since completion, the project has significantly improved access to clean drinking water for isolated communities in the Kalpitiya region. Prior to the project completion, 350 local families and approximately 100 Sri Lanka Air Force and Civil Security Force personnel relied on a tube well with high salinity, forcing villagers to travel 5km for water or buy bottled supplies, with the Air Force required to transport water from 50km away, on a weekly basis. The project created access to safe, accessible water; drastically reducing the burden on residents and civil security staff.

MAS Fabric Park

MAS Fabric Park (MFP) is an MAS-owned manufacturing zone housing a number of apparel and textile facilities. MFP provides utility services for each of its facilities:

In-House Water Treatment and Distribution, with a capacity of up to 9,000 Cu.m/day. MFP treats and distributes the water as per the SLS 614 and WHO standards. This system generates around 62% of the Group’s total water requirement.

In-House Wastewater Management and Disposal, with an installed capacity of up to 8,500 Cu.m/day. MFP treats and discharges wastewater according to national standards and globally accepted ZDHC protocols. MFP CETP manages and treats up to 60% of the total wastewater generated by the Group.

An in-house water and wastewater quality testing lab, accredited by the Sri Lanka Accreditation Board (SLAB), maintains operations compliant with the ISO IEC 17025 Laboratory Management System. The Lab is registered with Sri Lanka’s Central Environment Authority (CEA), and maintains compliant testing while providing faster feedback, and conducting R&D for all the above process.

Textile production effluent (wet sludge management and in-house co-incinerations) – MFP handles almost 100% of the Group’s textile sludge volume. Sludge is dewatered from 75% M.C. to 25% M.C. using a Solar Drier (at Biyagama) and Biomass Driers (at MFP). In-House Co-Incinerations are carried out at a newly commissioned 17 Ton customised multifuelled boiler (Biomass + Dried textile sludge). Of the final output, heavy ash and slag are used for the production of cement blocks (ECO Bricks).

MFP operates Sri Lanka’s very first industrial composting project implemented for Organic Waste generated at the Industrial Processing Zone. The composting system has the capacity to produce 2,000 tons of Compost per annum. The massive impact of the project was recognised at the MAS Changemaker Awards 2023, under the Planet category.

Photon Phase I and II, are housed within MFP, with an installed capacity of 22.84 MW across MAS facilities and estimated annual generation of 29 GWh. The estimated carbon footprint reduction from the Photon project amounts to around 17,800 TCO2e per year.